Metal Surface Catalytic Alloy (Nickel Phosphorus Coating)

Product performance features

1. Uniform thickness of the coating: the average thickness change within ± 5%, no permeability limit, strictly maintain the geometry of the coated workpiece.

2. Strong adhesion of the coating: on the substrate surface is the compressive stress, the binding force is generally 400Mpa.

3. High hardness of the coating: surface hardness up to 550HV, good wear resistance.

4. Good temperature resistance of the coating: at 700 ℃ not Soften, no peeling, do not fall off.

5. Good compactness of the coating: low porosity, coating greater than 30μm, can be achieved without pinhole.

6. Good integrity of the coating: the elongation is 0.5%-1.5% can be fully bent without cracks.

Scope of application

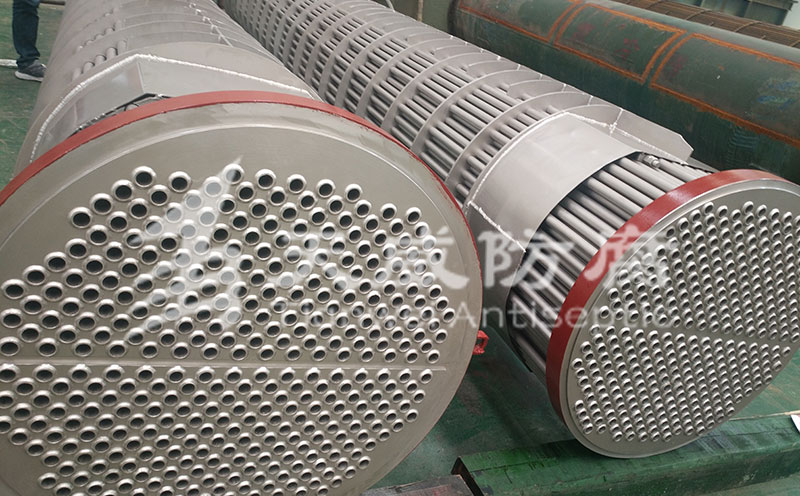

The excellent properties of Ni-P alloy coating with high corrosion resistance and the successful application of this technology in petroleum processing enterprises over the years have solved the corrosion problems of such as HCL, H2S, FeCL3 and naphthenic acid encountered in production. In many systems of refinery production plants such as usual decompression device fractionation system, heavy oil catalytic cracking unit, delayed coking device, catalytic reforming device, gas fractionation device, hydrogenation device, sulfuric acid recovery device, aromatic extraction device and other systems, operating temperature in the 100℃-380℃ range, the working medium contains H2S,Sulfur and sulfide monomer, Naphthenic acid, HCL and CL-components and other corrosive media equipment, can be used Ni-P alloy coating process technology. It can effectively solve the equipment encountered by high temperature sulfur corrosion, FeCL3 corrosion, inorganic acid and organic acid and other acidic media caused by chemical corrosion, H2S caused by stress corrosion cracking, CL-formation of point corrosion and many other corrosion problems, to ensure the safe operation of equipment.

Multifunctional electroless plating Ni-P alloy technology can be widely used in oil extraction, oil processing enterprises in heat transfer equipment, coil, injection well oil pipe, control pump valve, instrumentation, absorption piston rod, rotary shaft, impeller, mixer, reaction kettle, filter, center separator, etc., can also be used in fertilizer, metallurgy, automotive, electronics, shipbuilding , Textile, food and many other industries related equipment, play an active and effective protection role.